zprávy

zdroje zpráv:New Power Pack For Rugo™ Drone Light Meets FAA Night UAV Requirements

17.10.2018 17:23 GISCafe.com Webcasts-Webinars Reduced pricing on Rugo™ Light and Quick Swap® Power Pack plus new drone lighting bundlesOCEANSIDE, Calif., Oct. 16, 2018 — …

Bentley Systems Releases Open-Source Library: iModel.js

17.10.2018 17:20 GISCafe.com Webcasts-Webinars Open-source JavaScript library for creating immersive connections to infrastructure digital twinsLONDON — (BUSINESS WIRE) — October 17, …

Irish Government Award Bluesky a Contract to Supply Geographic Data

17.10.2018 17:19 GISCafe.com Webcasts-Webinars The Department for Agriculture, Food and the Marine (DAFM), has awarded Bluesky Ireland, a specialist in aerial mapping, a contract to supply high …Rheticus and ERDAS IMAGINE team up for ground displacement monitoring

17.10.2018 17:18 GISCafe.com Webcasts-Webinars Rheticus® Displacement service is now available in ERDAS IMAGINE 2018.Hexagon Geospatial has teamed up with Planetek Italia to offer a …

Maxar Technologies' DigitalGlobe Expands NASA Partnership with New Sole-Source Contract for Commercial Earth Observation Data

17.10.2018 17:17 GISCafe.com Webcasts-Webinars WESTMINSTER, CO, Oct. 17, 2018 — (PRNewswire) — DigitalGlobe, a Maxar Technologies company (NYSE: MAXR) (TSX: MAXR), today …BetterGIS Launches Its Powerful New Platform Nationwide, Offers Expanded Capabilities to Manage Utility and Facility Infrastructure

17.10.2018 17:16 GISCafe.com Webcasts-Webinars Streamlined Geographic Information System (GIS) is Easiest and Most Cost-Effective Way to Design, Plan, Build and Operate AssetsNOVATO, Calif. …

Global Aerial Imagery Market Report 2018: Size and Forecast 2014-2024 - ResearchAndMarkets.com

17.10.2018 17:15 GISCafe.com Webcasts-Webinars DUBLIN — (BUSINESS WIRE) — October 17, 2018 — The "Global Aerial Imagery Market by Application, by Vertical, by Type - Size and …referent KN – zápis do protokolu řízení V a Z

17.10.2018 17:02 ČÚZK - předpisy a opatření Katastrální úřad pro hlavní město Prahu - Katastrální pracoviště Prahavypisuje výběrové řízení na místo: referent KN – vedení DKM, vedení katastrální mapy

referent KN – zápis do protokolu řízení V a Z

referent KN – vedení DKM, vedení katastrální mapy

17.10.2018 17:02 ČÚZK - volná místa Katastrální úřad pro hlavní město Prahu - Katastrální pracoviště Praha vypisuje výběrové řízení na místo referent KN – vedení DKM, vedení katastrální mapyreferent KN – zápis do protokolu řízení V a Z

17.10.2018 17:02 ČÚZK - volná místa Katastrální úřad pro hlavní město Prahu - Katastrální pracoviště Praha vypisuje výběrové řízení na místo referent KN – zápis do protokolu řízení V a Zreferent KN – vedení DKM, vedení katastrální mapy

17.10.2018 17:02 ČÚZK - předpisy a opatření Katastrální úřad pro hlavní město Prahu - Katastrální pracoviště Prahavypisuje výběrové řízení na místo: referent KN – vedení DKM, vedení katastrální mapy

referent KN – vedení DKM, vedení katastrální mapy

referent KN – vedení DKM, vedení katastrální mapy

17.10.2018 17:02 ČÚZK /Urady/Katastralni-urady/Katastralni-urady/Katastralni-urad-pro-hlavni-mesto-Prahu/Uredni-deska/Oznameni-a-jina-uredni-sdeleni/Volna-mista/referent-KN-–-vedeni-DKM,-vedeni-katastralni-mapyreferent KN – zápis do protokolu řízení V a Z

17.10.2018 17:02 ČÚZK /Urady/Katastralni-urady/Katastralni-urady/Katastralni-urad-pro-hlavni-mesto-Prahu/Uredni-deska/Oznameni-a-jina-uredni-sdeleni/Volna-mista/referent-KN-–-vedeni-DKM,-vedeni-katastralni-mapyreferent KN – obnova katastrálního operátu

17.10.2018 16:58 ČÚZK - předpisy a opatření Katastrální úřad pro hlavní město Prahu - Katastrální pracoviště Prahavypisuje výběrové řízení na místo

referent KN – obnova katastrálního operátu

referent KN – vedení DKM, vedení katastrální mapy

17.10.2018 16:58 ČÚZK - předpisy a opatření Katastrální úřad pro hlavní město Prahu - Katastrální pracoviště Prahavypisuje výběrové řízení na místo

referent KN – vedení DKM, vedení katastrální mapy

referent KN – obnova katastrálního operátu

17.10.2018 16:58 ČÚZK - volná místa Katastrální úřad pro hlavní město Prahu - Katastrální pracoviště Praha vypisuje výběrové řízení na místo referent KN – obnova katastrálního operátureferent KN – vedení DKM, vedení katastrální mapy

17.10.2018 16:58 ČÚZK /Urady/Katastralni-urady/Katastralni-urady/Katastralni-urad-pro-hlavni-mesto-Prahu/Uredni-deska/Oznameni-a-jina-uredni-sdeleni/Volna-mista/referent-KN-–-obnova-katastralniho-operatureferent KN – obnova katastrálního operátu

17.10.2018 16:58 ČÚZK /Urady/Katastralni-urady/Katastralni-urady/Katastralni-urad-pro-hlavni-mesto-Prahu/Uredni-deska/Oznameni-a-jina-uredni-sdeleni/Volna-mista/referent-KN-–-obnova-katastralniho-operatureferent KN – vedení DKM, vedení katastrální mapy

17.10.2018 16:58 ČÚZK - volná místa Katastrální úřad pro hlavní město Prahu - Katastrální pracoviště Praha vypisuje výběrové řízení na místo referent KN – vedení DKM, vedení katastrální mapyAktualizace dat ÚAP od poskytovatelů České radiokomunikace a ÚHUL

17.10.2018 15:40 Plzeňský kraj V datech územně analytických podkladů Plzeňského kraje byla provedena kompletní aktualizace dat ve správě poskytovatele České radiokomunikace a.s. a aktualizace dat od poskytovatele Ústav pro hospodářskou úpravu lesů Brandýs nad Labem.rada/vrchní referent – návrh zápisu, kontrola a zplatnění

17.10.2018 15:18 ČÚZK /Urady/Katastralni-urady/Katastralni-urady/Katastralni-urad-pro-hlavni-mesto-Prahu/Uredni-deska/Oznameni-a-jina-uredni-sdeleni/Volna-mista/rada-vrchni-referent-–-navrh-zapisu,-kontrola-(1)rada/vrchní referent – návrh zápisu, kontrola a zplatnění

17.10.2018 15:18 ČÚZK - volná místa Katastrální úřad pro hlavní město Prahu - Katastrální pracoviště Praha vypisuje výběrové řízení na místo rada/vrchní referent – návrh zápisu, kontrola a zplatněnírada/vrchní referent – návrh zápisu, kontrola a zplatnění

17.10.2018 15:18 ČÚZK - předpisy a opatření Katastrální úřad pro hlavní město Prahu - Katastrální pracoviště Prahavypisuje výběrové řízení na místo

rada/vrchní referent – návrh zápisu, kontrola a zplatnění

4th Horizon 2020 EGNSS Call now open

17.10.2018 13:53 European GNSS Agency

The 4th Horizon 2020 EGNSS Call opened on October 16, with four topics that leverage EGNSS innovation to energise economic growth, foster digitisation and support environmental sustainability, particularly in Europe’s cities. So, let’s take a look at the many R&D funding opportunities available to the GNSS community within this call.

The 4th EGNSS-related call aims to foster the emergence of new innovative downstream applications based on Galileo and/or EGNOS and support the EU GNSS industry, SMEs, universities, research organisations and public bodies.

The specific challenge of the first topic of the call is to address the EGNSS applications fostering green, safe and smart mobility, with the objective of developing innovative EGNSS-based applications that lead to low-emission, safer, more cost-effective and higher performance mobility and transport solutions, responding to the growing mobility needs of people and goods.

Mass market and the environment

The second topic of the call addresses EGNSS applications fostering digitisation, and its main challenge is to develop EGNSS applications contributing to digitisation of products and services that will address major societal challenges in focus areas such as health, citizen safety, mobility, smart cities, sustainable resources monitoring and management and regional growth.

The third topic, on EGNSS applications fostering societal resilience and protecting the environment, aims to develop innovative EGNSS applications to support societal resilience, safeguard the wellbeing of EU citizens, improve emergency and disaster management as a response to climate-related natural and man-made disasters, and promote green growth.

Finally, the last topic of Awareness raising and capacity building, aims to build a mechanism to leverage EGNSS excellence, to provide opportunities to create networks of industrial relationships in Europe and globally, and facilitate EGNSS investments.

For more information on all of these calls, click here.

Horizon 2020 Info Day

Ahead of the call, the GSA together with the European Commission and COSMOS2020, the network of National Contact Points for Space, co-organised a Horizon 2020 International Space Information Day and Brokerage Event at the GSA’s Prague headquarters on 11-12 October 2018.

The event was organised to inform participants about space opportunities in Horizon 2020 and beyond and to provide first-hand information on the latest H2020 Space Calls, with a special focus on the 4th H2020 EGNSS Call, including a detailed description of all topics, submission and financial rules as well as the evaluation process.

Horizon 2020 International Space Information Day and Brokerage Event at the GSA’s Prague headquarters

Over the two day event, more than 130 participants from 28 countries were updated on the status of Galileo and Copernicus and on the synergies arising from these two flagship programmes. In addition, through the brokerage sessions the participants had the opportunity to network and meet potential partners.

To view presentations from the Horizon 2020 Info Day, click here.

Media note: This feature can be republished without charge provided the European GNSS Agency (GSA) is acknowledged as the source at the top or the bottom of the story. You must request permission before you use any of the photographs on the site. If you republish, we would be grateful if you could link back to the GSA website (http://www.gsa.europa.eu).

4th Horizon 2020 EGNSS Call now open

17.10.2018 13:53 European GNSS Agency

The 4th Horizon 2020 EGNSS Call opened on October 16, with four topics that leverage EGNSS innovation to energise economic growth, foster digitisation and support environmental sustainability, particularly in Europe’s cities. So, let’s take a look at the many R&D funding opportunities available to the GNSS community within this call.

The 4th EGNSS-related call aims to foster the emergence of new innovative downstream applications based on Galileo and/or EGNOS and support the EU GNSS industry, SMEs, universities, research organisations and public bodies.

The specific challenge of the first topic of the call is to address the EGNSS applications fostering green, safe and smart mobility, with the objective of developing innovative EGNSS-based applications that lead to low-emission, safer, more cost-effective and higher performance mobility and transport solutions, responding to the growing mobility needs of people and goods.

Mass market and the environment

The second topic of the call addresses EGNSS applications fostering digitisation, and its main challenge is to develop EGNSS applications contributing to digitisation of products and services that will address major societal challenges in focus areas such as health, citizen safety, mobility, smart cities, sustainable resources monitoring and management and regional growth.

The third topic, on EGNSS applications fostering societal resilience and protecting the environment, aims to develop innovative EGNSS applications to support societal resilience, safeguard the wellbeing of EU citizens, improve emergency and disaster management as a response to climate-related natural and man-made disasters, and promote green growth.

Finally, the last topic of Awareness raising and capacity building, aims to build a mechanism to leverage EGNSS excellence, to provide opportunities to create networks of industrial relationships in Europe and globally, and facilitate EGNSS investments.

For more information on all of these calls, click here.

Horizon 2020 Info Day

Ahead of the call, the GSA together with the European Commission and COSMOS2020, the network of National Contact Points for Space, co-organised a Horizon 2020 International Space Information Day and Brokerage Event at the GSA’s Prague headquarters on 11-12 October 2018.

The event was organised to inform participants about space opportunities in Horizon 2020 and beyond and to provide first-hand information on the latest H2020 Space Calls, with a special focus on the 4th H2020 EGNSS Call, including a detailed description of all topics, submission and financial rules as well as the evaluation process.

Horizon 2020 International Space Information Day and Brokerage Event at the GSA’s Prague headquarters

Over the two day event, more than 130 participants from 28 countries were updated on the status of Galileo and Copernicus and on the synergies arising from these two flagship programmes. In addition, through the brokerage sessions the participants had the opportunity to network and meet potential partners.

Media note: This feature can be republished without charge provided the European GNSS Agency (GSA) is acknowledged as the source at the top or the bottom of the story. You must request permission before you use any of the photographs on the site. If you republish, we would be grateful if you could link back to the GSA website (http://www.gsa.europa.eu).

4th Horizon 2020 EGNSS Call now open

17.10.2018 13:53 European GNSS Agency

The 4th Horizon 2020 EGNSS Call opened on October 16, with four topics that leverage EGNSS innovation to energise economic growth, foster digitisation and support environmental sustainability, particularly in Europe’s cities. So, let’s take a look at the many R&D funding opportunities available to the GNSS community within this call.

The 4th EGNSS-related call aims to foster the emergence of new innovative downstream applications based on Galileo and/or EGNOS and support the EU GNSS industry, SMEs, universities, research organisations and public bodies.

The specific challenge of the first topic of the call is to address the EGNSS applications fostering green, safe and smart mobility, with the objective of developing innovative EGNSS-based applications that lead to low-emission, safer, more cost-effective and higher performance mobility and transport solutions, responding to the growing mobility needs of people and goods.

Mass market and the environment

The second topic of the call addresses EGNSS applications fostering digitisation, and its main challenge is to develop EGNSS applications contributing to digitisation of products and services that will address major societal challenges in focus areas such as health, citizen safety, mobility, smart cities, sustainable resources monitoring and management and regional growth.

The third topic, on EGNSS applications fostering societal resilience and protecting the environment, aims to develop innovative EGNSS applications to support societal resilience, safeguard the wellbeing of EU citizens, improve emergency and disaster management as a response to climate-related natural and man-made disasters, and promote green growth.

Finally, the last topic of Awareness raising and capacity building, aims to build a mechanism to leverage EGNSS excellence, to provide opportunities to create networks of industrial relationships in Europe and globally, and facilitate EGNSS investments.

For more information on all of these calls, click here.

Horizon 2020 Info Day

Ahead of the call, the GSA together with the European Commission and COSMOS2020, the network of National Contact Points for Space, co-organised a Horizon 2020 International Space Information Day and Brokerage Event at the GSA’s Prague headquarters on 11-12 October 2018.

The event was organised to inform participants about space opportunities in Horizon 2020 and beyond and to provide first-hand information on the latest H2020 Space Calls, with a special focus on the 4th H2020 EGNSS Call, including a detailed description of all topics, submission and financial rules as well as the evaluation process.

Horizon 2020 International Space Information Day and Brokerage Event at the GSA’s Prague headquarters

Over the two day event, more than 130 participants from 28 countries were updated on the status of Galileo and Copernicus and on the synergies arising from these two flagship programmes. In addition, through the brokerage sessions the participants had the opportunity to network and meet potential partners.

To view presentations from the Horizon 2020 Info Day, click here.

Media note: This feature can be republished without charge provided the European GNSS Agency (GSA) is acknowledged as the source at the top or the bottom of the story. You must request permission before you use any of the photographs on the site. If you republish, we would be grateful if you could link back to the GSA website (http://www.gsa.europa.eu).

OGC adopts new revision to GML in JPEG 2000 (GMLJP2), allowing standardized markup for rectified and referenceable imagery

17.10.2018 13:48 GISCafe.com Webcasts-Webinars Version 2.1 transitions GMLJP2 from an imagery format restricted to rectified ‘map’ images to a more general format that supports …Diskusní setkání Building Information Modeling (BIM) a jeho využití v praxi

17.10.2018 13:39 Asociace podnikatelů v geomatice Asociace podnikatelů v geomatice (APG) zve na ojedinělé setkání profesionálů v oblasti BIM, kteří srozumitelně a lidsky vysvětlí tematiku Building Information Modeling a jeho využití v praxi. Registrace na setkání 7. listopadu 2018 Čas: 10:00 – 12:00 Místo konání CAMP Praha Vyšehradská 2075/51 128 00 Praha 2 – Nové Město, Telefon: +420 770 141 547 Web: http://praha.camp/ Jaká jsou témata diskusního setkání? O čem se bude […]PAE ISR Partners with NASA for 2020 Unmanned Aircraft Demo in US Airspace

17.10.2018 13:13 GISCafe.com Webcasts-Webinars STERLING, Va., October 16, 2018 - PAE ISR, LLC, the original equipment manufacturer of the Resolute Eagle, signed a cooperative agreement with NASA …Leica Geosystems introduces new generation of manual total stations

17.10.2018 12:30 GISCafe.com Webcasts-Webinars World’s first AutoHeight feature enables automatic instrument height setting(Heerbrugg, Switzerland – 17 October 2018) – …

GEPRO&ATLAS 2018 – aktuální verze programu

17.10.2018 12:24 GEPROByla publikována aktuální verze programu Setkání uživatelů produktů a služeb společností GEPRO & ATLAS 2018.… >>

GEPRO&ATLAS 2018 – aktuální verze programu

17.10.2018 12:24 GEPROByla publikována aktuální verze programu Setkání uživatelů produktů a služeb společností GEPRO & ATLAS 2018.… >>

GNSS Emergency Warning Service successfully tested

17.10.2018 11:21 European GNSS Agency

In the framework of GNSS cooperation between the European Union and Japan, a test was recently conducted of a GNSS-based global Emergency Warning Service using Japan’s Quasi-Zenith Satellite System (QZSS), which delivered impressive results.

The European Union is looking into the potential for deploying a new, global, emergency warning service (EWS) based on the EU Space Programme Galileo, as part of the EU Horizon 2020-funded GRALLE project (Galileo-based Reliable Automatic and Low Latent Emergency warning service).

Tested with QZSS

As the service should be based on a common alert protocol, one of the elements of the project is the development of a common alert messaging standard with QZSS, Japan’s satellite-based augmentation system (SBAS). This was the reason behind the recent test of the system with QZSS in a suburb of Melbourne, Australia.

During the test, an alert message was prepared warning of a fire in the Melbourne suburb and uploaded in the ground segment of the QZSS system. The message was then uplinked to the QZSS satellites and broadcast to smartphones in the alert zone.

A prototype receiver using a smartphone in the alert zone received messages with instructions to follow based on where in the zone they were located. Some users were advised to remain inside and wait for emergency services to arrive, while others were instructed to leave the area and proceed to a pre-determined meeting point.

Smartphone users received messages with instructions to follow based on where in the alert zone they were located

Smartphone users received messages with instructions to follow based on where in the alert zone they were located

The test was performed with only the L1S signal from QZSS, meaning that no other communication infrastructure (e.g. mobile towers) was used. The local Australian civil protection authorities who took part in the test were very impressed with the results.

Many benefits

European Commission Project Officer Frédéric Domps highlighted the many benefits of the project. “A GNSS-based Emergency Warning System will bring significant advantages for countries that do not currently have such a system, and even for countries that already have a land-based system,” he said, adding that a Galileo-based Emergency Warning Service would be global in its scope, resilient to ground damage and deployable in response to all types of hazards, from earthquakes to forest fires and terrorist attacks.

“The next steps should involve the conducting of further testing and refinement of the service definition,” Domps said.

Timeline

It is planned that the concept will be refined in 2019 with the objective of reaching a decision for implementation with the relevant EU organisations. Service deployment should then proceed with the objective of having a fully operational service in the 2023 timeframe.

Media note: This feature can be republished without charge provided the European GNSS Agency (GSA) is acknowledged as the source at the top or the bottom of the story. You must request permission before you use any of the photographs on the site. If you republish, we would be grateful if you could link back to the GSA website (http://www.gsa.europa.eu).

Zapište si do kalendáře termín INSPIRE info day

17.10.2018 11:01 CENIA - národní geoportál INSPIRE Uložte si do svých kalendářů termín pro INSPIRE info day. Akce proběhne 7.12.2018 v čase 10.00 - 15.00 v zasedací místnosti ČÚZK (Pod Sídlištěm 9/1800, Praha 8). Další informace budou zveřejněny v první polovině listopadu.Odborný referent/vrchní referent v oddělení právním na Katastrálním pracovišti Brno-venkov

17.10.2018 9:10 ČÚZK /Urady/Katastralni-urady/Katastralni-urady/Katastralni-urad-pro-Jihomoravsky-kraj/Uredni-deska/Oznameni-a-jina-uredni-sdeleni/Volna-mista/Odborny-referent-vrchni-referent-v-oddeleni-pr-(1)Odborný referent/vrchní referent v oddělení právním na Katastrálním pracovišti Brno-venkov

17.10.2018 9:10 ČÚZK - předpisy a opatření Katastrální úřad pro Jihomoravský kraj - Katastrální pracoviště Brno-venkovvypisuje výběrové řízení na místo

Odborný referent/vrchní referent v oddělení právním na Katastrálním pracovišti Brno-venkov

Odborný referent/vrchní referent v oddělení právním na Katastrálním pracovišti Brno-venkov

17.10.2018 9:10 ČÚZK - volná místa Katastrální úřad pro Jihomoravský kraj - Katastrální pracoviště Brno-venkov vypisuje výběrové řízení na místo Odborný referent/vrchní referent v oddělení právním na Katastrálním pracovišti Brno-venkovCurators at the Library of Congress Embrace Story Maps (ArcUser Online)

17.10.2018 9:00 GISCafe.com Webcasts-WebinarsUživatelské setkání T-Mapy očima GISportalu

17.10.2018 8:54 GISportal.cz

První dva dny v říjnu se konalo tradiční uživatelské setkání zákazníků společnosti T-Mapy. Na rozdíl od velkých setkání, typických například pro konference Esri, se jednalo o spíše menší akci, podle organizátorů okolo 135 účastníků z 62 organizací z Česka a Slovenska. Tato velikost však nebyla na škodu a ještě více podtrhovala “rodinnost” jak akce, tak […]

The post Uživatelské setkání T-Mapy očima GISportalu appeared first on GISportal.cz.

Inspektor Zeměměřického a katastrálního inspektorátu v Brně (obor služby 70.)

17.10.2018 7:21 ČÚZK /Urady/Zememericke-a-katastralni-inspektoraty/Zememericke-a-katastralni-inspektoraty/Zememericky-a-katastralni-inspektorat-v-Brne/Uredni-deska/Oznameni-a-jina-uredni-sdeleni/Volna-mista/Inspektor-Zememerickeho-a-katastralniho-inspek-(1)NIVA 21214 RZ 4B0 3905

17.10.2018 6:35 ČÚZK - předpisy a opatřeníKatastrální úřad pro Jihomoravský kraj nabízí nepotřebný majetek k odkupu. Jedná se o

NIVA 21214 RZ 4B0 3905

NIVA 21214 RZ 4B0 3905

17.10.2018 6:35 ČÚZK /Urady/Katastralni-urady/Katastralni-urady/Katastralni-urad-pro-Jihomoravsky-kraj/Nabidky-majetku/NIVA-21214-RZ-4B0-3905NIVA 21214 RZ 3B2 8028

17.10.2018 6:34 ČÚZK - předpisy a opatřeníKatastrální úřad pro Jihomoravský kraj nabízí nepotřebný majetek k odkupu. Jedná se o

NIVA 21214 RZ 3B2 8028

NIVA 21214 RZ 3B2 8028

17.10.2018 6:34 ČÚZK /Urady/Katastralni-urady/Katastralni-urady/Katastralni-urad-pro-Jihomoravsky-kraj/Nabidky-majetku/NIVA-21214-RZ-3B2-8028Bentley Systems Releases Open-Source Library: iModel.js

17.10.2018 2:00 Bentley SystemsOpen-source JavaScript library for creating immersive connections to

infrastructure digital twins

LONDON, U.K. – The Year in Infrastructure 2018 Conference – 17 October 2018 – Bentley Systems, Incorporated, the leading global provider of comprehensive software solutions for advancing the design, construction, and operations of infrastructure, today announced the initial release of its iModel.js library, an open-source initiative to improve the accessibility, for both visualization and analytical visibility, of infrastructure digital twins. iModel.js can be used by developers and IT professionals to quickly and easily create immersive applications that connect their infrastructure digital twins with the rest of their digital world. iModel.js is the cornerstone of Bentley’s just-announced iTwin™ Services that combine iModelHub, reality modeling, and web-enabling software technologies within a Connected Data Environment (CDE) for infrastructure engineering.

Bentley’s iModels have become a de facto standard for visibility into digital engineering models. iModelHub manages an iModel as a distributed database with an intrinsic ledger of changes—enabling alignment, accountability, and accessibility of its digital components—to form the backbone of an infrastructure digital twin.

The iModel.js library is a comprehensive collection of JavaScript packages that build on the most open, popular, and flexible standards for modern cloud and web development. It is written in TypeScript, and leverages open technologies including SQLite, Node.js, NPM, WebGL, Electron, Docker, Kubernetes, and of course HTML5 and CSS. The same codebase can produce cloud services and web, mobile, and desktop applications. The source code is hosted on GitHub and is distributed under the MIT license.

With iModel.js, it is simple to create a web-based experience that shows interactive “nD” views (1D, 2D, 3D, 4D, etc.) of iModels that are assembled and synchronized from BIM files and other digital engineering models, and from data created directly with iModel.js. Those same views can also include digital (reality) context, real-time sensor data, and other data from enterprise sources and analytics. Since the iModel is synchronized by iModelHub, it always reflects the most recent updates from all project participants, who are thus able to visualize and analyze changes between points in time or between versions. Importantly, only users and applications authorized by the iModel owner, through iModelHub, are granted access through iModel.js.

Johan Palm, program manager – Digital Project Delivery at Hatch, said, “iModel.js gives Hatch the ability to implement a stakeholder engagement technology that extends the iModelHub visionary technology. We can expose complex project information to a level that is accessible, consumable, and extendable via the cloud and in context to the 3D model. Most importantly we can do so in a manner that embraces change as the project progresses. iModel.js aligns with Hatch’s internal development strategies as it is built on modern, highly portable web technology. Bentley is a key software technology partner on Hatch projects globally where our main objective is to provide a positive impact to our client’s assets and operations.”

Cai Chengguo, chair and general manager, Shenzhen Expressway Consulting Group, said, “The digital twin powered by iModelHub is efficiently improving project management, substantially reducing the waste of resources caused by site problems and will achieve digital handover after completion of the project for visual operations and maintenance.”

Keith Bentley, Bentley Systems’ founder and CTO, said, “We firmly believe that iModel.js, and of course the foundation upon which it is built, is the most open, productive, intuitive, and powerful development environment for capital projects and infrastructure assets, ever. We’re excited to work with user organizations, strategic partners, and third-party developers to build an open ecosystem around iModels to tap the vast potential of infrastructure digital twins. With iModel.js, the well-refined techniques of mainstream cloud and web development can leverage the physical and virtual reality in digital twins with near-zero impedance. By open-sourcing the libraries we use to create our iTwin™ cloud services, we expect to foster a substantial and vibrant ecosystem of innovation.”

More about iModel.js: iModeljs.org

More about iModels and iModelHub: iModelHub.com

About Bentley Systems

Bentley Systems is the leading global provider of software solutions to engineers, architects, geospatial professionals, constructors, and owner-operators for the design, construction, and operations of infrastructure. Bentley’s MicroStation-based engineering and BIM applications, and its digital twin cloud services, advance the project delivery (ProjectWise) and the asset performance (AssetWise) of transportation and other public works, utilities, industrial and resources plants, and commercial and institutional facilities.

Bentley Systems employs more than 3,500 colleagues, generates annual revenues of $700 million in 170 countries, and has invested more than $1 billion in research, development, and acquisitions since 2012. From inception in 1984, the company has remained majority-owned by its five founding Bentley brothers. Bentley shares transact by invitation on the NASDAQ Private Market; strategic partner Siemens AG has accumulated a non-voting minority stake.

###

Bentley, the Bentley logo, AssetWise, Connected Data Environment, iTwin, MicroStation, and ProjectWise are either registered or unregistered trademarks or service marks of Bentley Systems, Incorporated or one of its direct or indirect wholly owned subsidiaries. All other brands and product names are trademarks of their respective owners.

Oznámení o částečném omezení provozu Pobočky Plzeň

17.10.2018 0:00 Státní pozemkový úřad Z důvodu malování kanceláří bude ve dnech úterý 30. 10. až úterý 6.11.2018 částečně omezen provoz Pobočky Plzeň (KPÚ pro Plzeňský kraj). Chod pobočky bude zajištěn.Minulý týden jsme se účastnili na pozvání setkání přátel civilního letectví na Ministerstvu dopravy

16.10.2018 21:53 UpVision Účastnili jsme se minulý týden příjemného setkání přátel civilního letectví na Ministerstvu dopravy k příležitosti 100 let vzniku republiky. Kromě detailní historie pražského letiště zazněly i vize jeho budoucnosti, včetně budoucího vývoje ŘLP a došlo samozřejmě i na drony.Zde více:

https://plus.google.com/u/0/b/115833877689730865211/+UpvisionCz1/posts/56Yi3sQ67cR

Invest in Murcia Launches First Online Business Location Analysis Service in Spain

16.10.2018 19:28 GISCafe.com Webcasts-Webinars GIS Planning software allows Region of Murcia to offer free, data-driven analysis to prospective businessesMURCIA, Spain, Oct. 16, 2018 — …

DJI Launches The Phantom 4 RTK Globally

16.10.2018 19:26 GISCafe.com Webcasts-Webinars SHENZHEN, China, Oct. 16, 2018 — (PRNewswire) — DJI, the world's leader in civilian drones and aerial imaging technology, today …Leidos awarded £26.9 million Scottish Government technology contract

16.10.2018 19:25 GISCafe.com Webcasts-Webinars EDINBURGH, Scotland, Oct. 15, 2018 — (PRNewswire) — Leidos (NYSE: LDOS), a FORTUNE® 500 science and technology company, has …Going Digital (Twins): Bentley Inaugurates iTwin™ Services!

16.10.2018 19:23 GISCafe.com Webcasts-Webinars Confluence of technologies enables project digital twins and performance digital twins for infrastructure engineering

LONDON — …

Maxar Technologies' DigitalGlobe Partners with Vodafone to Create an IoT Precision Agriculture Product

16.10.2018 19:22 GISCafe.com Webcasts-Webinars WESTMINSTER, CO, Oct. 16, 2018 — (PRNewswire) — DigitalGlobe, a Maxar Technologies company (NYSE: MAXR) (TSX: MAXR), today …Drone Aviation Delivers on $1.7 Million Contract for WASP Tactical Aerostat to U.S. Department of Defense

16.10.2018 19:21 GISCafe.com Webcasts-Webinars JACKSONVILLE, FL, Oct. 16, 2018 (GLOBE NEWSWIRE) -- Drone Aviation Holding Corp. (OTCQB: DRNE) (“Drone Aviation” or the …BAE Systems Successfully Demonstrates XTS Guard 5 for Military Cyber Security

16.10.2018 19:20 GISCafe.com Webcasts-Webinars RESTON, Va. — (BUSINESS WIRE) — October 16, 2018 — BAE Systems’ XTS® Guard 5, equipped with the company’s …Commercial Drone Poised to Emerge Game Changing in Drone Ecosystem through 2022, Says Fact.MR

16.10.2018 19:19 GISCafe.com Webcasts-Webinars Rockville, MD, Oct. 16, 2018 (GLOBE NEWSWIRE) -- DJI – the global drone leader, recently shipped 1000 Matrice drones equipped with machine …Blink Charging Co. Teams up with Google Maps

16.10.2018 19:18 GISCafe.com Webcasts-Webinars Blink Charging Co, a leading Electric Vehicle Charging Services Company, enhances its software to work seamlessly with Google Maps and makes it …Global Satellite Attitude and Orbit Control System Market 2018-2022 | Rise of Satellite-Aided Warfare to Promote Growth | Technavio

16.10.2018 19:17 GISCafe.com Webcasts-Webinars LONDON — (BUSINESS WIRE) — October 16, 2018 — The global satellite attitude and orbit control system market is expected to post a …GSA survey targets user-driven RPAS/Drones applications

16.10.2018 15:58 European GNSS Agency

The European GNSS Agency (GSA) is currently conducting a survey among operators and manufacturers of remotely piloted aircraft systems (RPAS) and aviation authorities with a view to better understanding user needs and identifying key requirements for future EGNSS upgrades and evolutions.

Various studies have shown the growing impact that RPAS will have on our daily lives. In fact, RPAS have already started bringing significant benefits all over Europe and the market is set to continue growing, in line with growth in the number applications. These applications come in a great variety including, but not limited to, delivery services, aerial photography and mapping, and precision agriculture.

Read this: EGNOS and Galileo – opening the door to new drone applications

Europe has the opportunity to obtain a significant role in this rapidly evolving global marketplace but, in order to unlock this opportunity actions are needed at the EU level to both boost innovative capabilities and implement comprehensive regulation to create a single drone market.

Have your say!

GNSS is the backbone technology underpinning the navigation solutions used for RPAS applications and this is expected to remain true in the future. For this reason, the GSA wants to make sure that EGNSS continues to meet the requirements and expectations of the RPAS user community. But, to do this, we need some input from you.

We have put together a short RPAS user requirements survey to help us better understand the needs and requirements of RPAS users. The survey consists of approximately 20 questions, and should not take longer than five minutes of your time to fill in. You can access the survey here – it will remain open until 30 November 2018, but there is no time like the present!

By filling in this survey, you will help the GSA to better understand user needs and the value that users attribute to GNSS. With this information, we can deduce the requirements of future EGNSS upgrades and evolutions. The survey is intended for all stakeholders in the RPAS value chain, but it is mainly focussed on operators, manufacturers of RPAS and navigation systems, and aviation authorities.

Media note: This feature can be republished without charge provided the European GNSS Agency (GSA) is acknowledged as the source at the top or the bottom of the story. You must request permission before you use any of the photographs on the site. If you republish, we would be grateful if you could link back to the GSA website (http://www.gsa.europa.eu).

GSA survey targets user-driven RPAS/Drones applications

16.10.2018 15:58 European GNSS Agency

The European GNSS Agency (GSA) is currently conducting a survey among operators and manufacturers of remotely piloted aircraft systems (RPAS) and aviation authorities with a view to better understanding user needs and identifying key requirements for future EGNSS upgrades and evolutions.

Various studies have shown the growing impact that RPAS will have on our daily lives. In fact, RPAS have already started bringing significant benefits all over Europe and the market is set to continue growing, in line with growth in the number applications. These applications come in a great variety including, but not limited to, delivery services, aerial photography and mapping, and precision agriculture.

Read this: EGNOS and Galileo – opening the door to new drone applications

Europe has the opportunity to obtain a significant role in this rapidly evolving global marketplace but, in order to unlock this opportunity actions are needed at the EU level to both boost innovative capabilities and implement comprehensive regulation to create a single drone market.

Have your say!

GNSS is the backbone technology underpinning the navigation solutions used for RPAS applications and this is expected to remain true in the future. For this reason, the GSA wants to make sure that EGNSS continues to meet the requirements and expectations of the RPAS user community. But, to do this, we need some input from you.

We have put together a short RPAS user requirements survey to help us better understand the needs and requirements of RPAS users. The survey consists of approximately 20 questions, and should not take longer than five minutes of your time to fill in. You can access the survey here – it will remain open until 30 November 2018, but there is no time like the present!

By filling in this survey, you will help the GSA to better understand user needs and the value that users attribute to GNSS. With this information, we can deduce the requirements of future EGNSS upgrades and evolutions. The survey is intended for all stakeholders in the RPAS value chain, but it is mainly focussed on operators, manufacturers of RPAS and navigation systems, and aviation authorities.

Media note: This feature can be republished without charge provided the European GNSS Agency (GSA) is acknowledged as the source at the top or the bottom of the story. You must request permission before you use any of the photographs on the site. If you republish, we would be grateful if you could link back to the GSA website (http://www.gsa.europa.eu).

Ze Země na Měsíc: vzdělávací cesta vesmírem na podzimním učitelském workshopu ESA

16.10.2018 15:54 Český Kosmický PortálBěhem Světového kosmického týdne na počátku tohoto měsíce padesát učitelů základních a středních škol z různých členských zemí a spolupracujících států ESA sdílelo své zkušenosti a nechalo se inspirovat vesmírem na podzimním učitelském workshopu ESA.

Valné shromáždění EuroGeographics v Praze

16.10.2018 15:47 GeoBusiness Ve dnech 8. až 10. října 2018 se v Praze sešli zástupci mezinárodní organizace EuroGeographics, která sdružuje evropské národní mapovací, pozemkové a katastrální instituce. ... PřečístHybrid+ (What have they come up with now?)

16.10.2018 15:37 Carlson Software ……an advanced field solution for collecting data. When I first learned about this new module for SurvCE it was at the Go West user’s conference in San Diego last spring. I watched a demo of what was then a beta version of the software and being the practical application kind of person I am, was […]Den GIS na Katedře geoinformatiky

16.10.2018 13:21 15.11. Den GIS na Katedře geoinformatiky Seminář s praktickými ukázkami na počítačové učebně. Jedná se o 2hod. blok, který bude obsahovat krátké představení GIS a následně praktické ukázky využití GIS. Začátek jednotlivých bloků budou: 8:00, 10:10 a 12:30, příp. 14:40 (max. 36 studentů na 1 blok). DŮLEŽITÉ: Kapacita akce je omezena – nutná registrace na: […]Den GIS ve Světě techniky

16.10.2018 13:18 14.11. Den GIS ve Světě techniky Akce proběhne v prostorách Velkého světa techniky v Ostravě. 9:00 – malé povídání o GIS (doporučeno pro 2. stupeň ZŠ) 9:45 – krátká přednáška o GIS (doporučeno pro SŠ, VŠ) od 9:30 – akční blok: – expozice STC – ukázka geocachingu (start 10:30, Divadlo vědy) – lezecká stěna TENDON […]Phase One Industrial Launches 150MP Metric Camera and New Aerial Systems

16.10.2018 10:55 GISCafe.com Webcasts-Webinars iXM Platform with Advanced Imaging Sensors Delivers Superior Aerial MappingCOPENHAGEN, August 28, 2018 – Phase One Industrial, a leading …

Odborný referent v oddělení dokumentace katastru nemovitostí Katastrálního pracoviště Jičín

16.10.2018 9:26 ČÚZK - volná místa Katastrální úřad pro Královéhradecký kraj - Katastrální pracoviště Jičín vypisuje výběrové řízení na místo Odborný referent v oddělení dokumentace katastru nemovitostí Katastrálního pracoviště JičínOdborný referent v oddělení dokumentace katastru nemovitostí Katastrálního pracoviště Jičín

16.10.2018 9:26 ČÚZK /Urady/Katastralni-urady/Katastralni-urady/Katastralni-urad-pro-Kralovehradecky-kraj/Uredni-deska/Oznameni-a-jina-uredni-sdeleni/Volna-mista/Odborny-referent-v-oddeleni-dokumentace-katastru-nOdborný referent v oddělení dokumentace katastru nemovitostí Katastrálního pracoviště Jičín

16.10.2018 9:26 ČÚZK - předpisy a opatření Katastrální úřad pro Královéhradecký kraj - Katastrální pracoviště Jičínvypisuje výběrové řízení na místo

Odborný referent v oddělení dokumentace katastru nemovitostí Katastrálního pracoviště Jičín

uzavření kp pr 29.10.2018

16.10.2018 9:25 ČÚZK - předpisy a opatření Katastrální úřad pro Olomoucký kraj - Katastrální pracoviště Přerov zveřejnil novou aktualitu:OZNÁMENÍ.

V pondělí 29. října 2018 bude katastrální pracoviště z důvodu přerušení dodávky elektřiny provozovatelem distribuční soustavy společností ČEZ Distribuce, a.s. UZAVŘENO.

uzavření kp pr 29.10.2018

16.10.2018 9:25 ČÚZK - předpisy a opatření Katastrální úřad pro Olomoucký kraj - Katastrální pracoviště Přerov zveřejnil novou aktualitu: OZNÁMENÍ. V pondělí 29. října 2018 bude katastrální pracoviště z důvodu přerušení dodávky elektřiny provozovatelem distribuční soustavy společností ČEZ Distribuce, a.s. UZAVŘENO.Děkujeme za pochopení.

uzavření kp pr 29.10.2018

16.10.2018 9:25 ČÚZK /Urady/Katastralni-urady/Katastralni-urady/Katastralni-urad-pro-Olomoucky-kraj/Katastralni-pracoviste/KP-Prerov/O-uradu/Aktuality/uzavzeni-kp-pr-29-10-2018Reveal Relationships, Patterns in Microsoft Power BI (ArcNews Online)

16.10.2018 9:00 GISCafe.com Webcasts-WebinarsGeospatial Intelligence Center Mounts Large Scale Aerial Imaging Response to Hurricane Michael

16.10.2018 9:00 GISCafe.com Webcasts-Webinars GIC provided imagery less than 24 hours from collection, where it was made accessible to GIC member insurers, NOAA, FEMA, Red Cross and first …Aktualizace dat ÚAP od poskytovatele ČEZ Distribuce, a.s. a Telco Pro Services, a.s.

16.10.2018 8:30 Plzeňský kraj V datech územně analytických podkladů Plzeňského kraje byla provedena aktualizace dat technické infrastruktury od poskytovatele ČEZ Distribuce, a. s. a Telco Pro Services, a.s. Data jsou s platností k 1. 10. 2018.Crowdsourcing počtvrté a naposledy aneb zpět k traktorovému preciznímu zemědělství

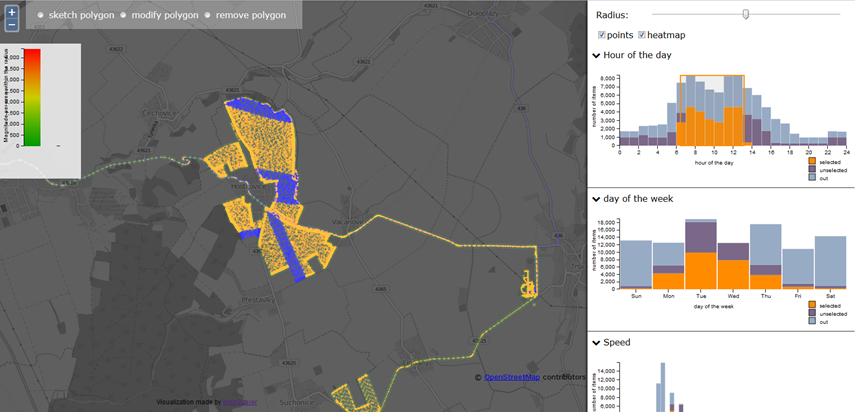

16.10.2018 7:15 GISportal.cz

Závěrečný díl miniseriálu představuje historicky nejstarší z představených crowdsourcingových aplikací. První sledování zemědělských strojů v našich aplikacích, tj. traktoru a přípojného zařízení, započalo v roce 2014, kontinuální měření pro 9 traktorů a 23 přípojných zařízení probíhá kontinuálně na testovacích farmách od března 2015 dosud. Kromě toho spolupracujeme nejen v rámci projektu DataBio přímo se společností Zetor, a.s. Nástroje vizuální […]

The post Crowdsourcing počtvrté a naposledy aneb zpět k traktorovému preciznímu zemědělství appeared first on GISportal.cz.

rada/odborný rada v oddělení obnovy katastrálního operátu (3020) – obnova katastrálního operátu Kata

16.10.2018 6:32 ČÚZK /Urady/Katastralni-urady/Katastralni-urady/Katastralni-urad-pro-Jihocesky-kraj/Uredni-deska/Oznameni-a-jina-uredni-sdeleni/Volna-mista/rada-odborny-rada-v-oddeleni-obnovy-katastralnihorada/odborný rada v oddělení obnovy katastrálního operátu (3020) – obnova katastrálního operátu Kata

16.10.2018 6:32 ČÚZK - volná místa Katastrální úřad pro Jihočeský kraj - odbor obnovy katastrálního operátu vypisuje výběrové řízení na místo rada/odborný rada v oddělení obnovy katastrálního operátu (3020) – obnova katastrálního operátu Katarada/odborný rada v oddělení obnovy katastrálního operátu (3020) – obnova katastrálního operátu Kata

16.10.2018 6:32 ČÚZK - předpisy a opatření Katastrální úřad pro Jihočeský kraj - odbor obnovy katastrálního operátuvypisuje výběrové řízení na místo

rada/odborný rada v oddělení obnovy katastrálního operátu (3020) – obnova katastrálního operátu Katastrálního úřadu pro Jihočeský kraj

INSPIRE téma Rozšířené Parcely (CPX)

16.10.2018 2:00 Cenia - Katalog metadat ČR - INSPIRE Rozšíření má za cíl poskytovat katastrální mapu s obsahem podle vyhlášky ve vektorové podobě ve struktuře plně v souladu se strukturou danou směrnicí INSPIRE. Data rozšiřují směrnici INSPIRE pro téma katastrální parcely (CP) o věcná břemena, geodetické body, další prvky mapy, původní obloukovou geometrii a o parcely určené definičním bodem (ty pouze v oblastech s analogovou mapou). Vychází z katastrální mapy, která je závazným státním mapovým dílem velkého měřítka, obsahuje body polohového bodového pole, polohopis a popis a může mít formu digitální mapy, analogové mapy nebo digitalizované mapy. Publikovaná data obsahují katastrální území pro celou Českou Republiku, parcely a jejich hranice, věcná břemena, další prvky mapy a původní obloukovou geometrii z území, kde je digitální mapa (k 26. 11. 2018 je to 96,16% území České republiky, t.j. 75 840,00km2) a ve zbytku území katastrální parcely určené pouze definičním bodem (tedy bez hranic a polygonu). Katastrální parcely a hranice obsahují oproti datové sadě INSPIRE některé atributy navíc. Jedná se o typ hranice, způsob využití území, druh pozemku, vazbu na budovu a o mapové značky. Více katastrální zákon 344/1992 SB., katastrální vyhláška č.26/2007 Sb. v platném znění a INSPIRE Data Specification on Cadastral Parcels v 3.0.1. Data ve formátu GML 3.2.1 jsou validní proti schématu XML pro Rozšířené Parcely (CPX) ve verzi 4.0.Going Digital (Twins):<br> Bentley Inaugurates iTwin™ Services!

16.10.2018 2:00 Bentley SystemsConfluence of technologies enables project digital twins and performance digital twins for infrastructure engineering

LONDON, U.K. – The Year in Infrastructure 2018 Conference - 16 October 2018 – Bentley Systems, Incorporated, the leading global provider of comprehensive software solutions for advancing the design, construction, and operations of infrastructure, today announced the forthcoming availability of iTwin™ Services, digital twin cloud services for infrastructure projects (project digital twins) and assets (performance digital twins). iTwin™ Services can be transparently provisioned within Bentley’s Connected Data Environment (CDE) for ProjectWise and AssetWise users.

Requirements for Realizing the Potential of Infrastructure Digital Twins

Infrastructure asset owners and their teams have recognized the potential for leveraging digital twins in many ambitious use cases including the application of analytics, artificial intelligence (AI) and machine learning (ML) in simulations and decision support throughout the lifecycle of design, construction, and operations. To realize this potential, representations of assets need obviously to be digital—but to be safely relied upon as a twin there must be practical solutions for their synchronization to changing actual conditions in the real world. Moreover, merely capturing and representing physical conditions, including IoT inputs, can never be sufficient to understand, analyze, or model intended improvements, without also comprehending the “digital DNA” captured in the project or asset’s engineering specifications.

To actually be worthwhile, therefore, would-be digital twins for existing infrastructure must reliably synchronize reflections of both an asset’s physical reality, and its “virtuality” (engineering data). A digital twin can meet this requirement by geospatially converging the digital context (representing the physical) and digital components (representing the virtual), naturally resulting in an immersive environment for both visualization and analytics visibility.

To date, however, the evolving 3D physical reality of an as-operated asset has been too formidably difficult to capture digitally, let alone to keep up-to-date. Meanwhile, corresponding, as-operated engineering information tends to be unavailable or at best, dated, as typically an assortment of effectively inaccessible “dark data” in either opaque engineering files or unintelligent document formats. Bentley has now surmounted both of these challenges, with the confluence of its reality modeling, iModelHub, CDE, and web-visibility technologies.

Reality Modeling

A representation of any infrastructure asset’s physical reality can now be reliably captured and maintained through increasingly continuous surveys and Bentley’s reality modeling software, providing digital context in the form of “reality meshes”. Overlapping photographs and (as needed) supplemental laser scans, largely from drones and ground-level imagery, are processed to generate spatially-classified and engineering-ready reality meshes at any desired level of accuracy—within which each digital component can be automatically recognized and/or geospatially referenced. The reality mesh can provide an efficient and immersive visual “twin” to intuitively navigate for finding, viewing, and querying the associated information within, or related to, the asset’s digital engineering models.

Adding iModelHub within CDE

The challenge in comparably capturing and maintaining these engineering counterparts of the physical asset— its digital components—is the opacity of their existing representations, compounded by continuous changes. Bentley’s iModelHub, introduced in 2017, overcomes these hurdles through automated digital alignment (to achieve semantic consistency from otherwise dark data in known formats), and synchronization, based on change ledgers, corresponding to the CDE’s project workflows (ProjectWise) or configuration management (AssetWise).

Web Visibility

Once populated and synchronized by way of digital context and digital components, iTwin™ Services deliver their benefits through Bentley’s new (separately announced) open-source iModel.js library (iModeljs.org) for web-based immersive visualization. Infrastructure teams can easily develop custom applications that connect their digital twin for specific use cases by leveraging a vast open source ecosystem. In addition, a geospatially immersive environment for city-scale digital twins is now available through Bentley’s new OpenCities Planner services.

Introducing Project Digital Twins

ProjectWiseCONNECT Edition users of Bentley’s CDE can instantiate cloud-provisioned iTwin™ Services for any project without disruption to their existing ProjectWise workflows. iModelHub will then transparently create and maintain the project’s comprehensive iModel: a distributed database, with its intrinsic change ledger updated at each deliverable-in-progress check-in state. For each such update to engineering information, application-specific “information bridge” processing effectuates digital alignment of the iModel’s digital components.

To the extent of available reality modeling for the physical site, the CDE’s corresponding ContextShare service maintains updated digital context. The iModel’s digital components and ContextShare digital context are immersively merged through Navigator Web and iModel.js visualization, as authorized and secured by iModelHub.

Accordingly, iTwin™ Services enable comprehensive project status reviews to be continuously available, synchronized to any requested project state on the iModel change ledger timeline, and/or for visualization and analytics visibility into changes between any project timeline states. iTwin™ Services will also integrate Bentley’s SYNCHRO 4D construction modeling.

iTwin™ Services for project digital twins will be available early in 2019, with quarterly base subscription charges for each iTwin™ based upon its scale, in terms of digital components and digital context, and inclusive of cloud provisioning and web accessibility.

Adding Performance Digital Twins

The iModel.js library supports functionality to create and curate iTwins fit for particular asset performance purposes, including “agent” updating of “data lakes” for analytics visibility. This enables emerging AI and mixed reality technologies to be advantageously applied throughout an asset’s lifecycle, and across assets—relying, for assured fidelity spanning physical reality and engineering data, upon the necessary digital alignment, change synchronization, and immersive visualization uniquely provided by iTwin™Services.

Also at the Conference, Siemens and Bentley unveiled PlantSight™, a new range of cloud services to be jointly offered for as-operated digital twins of any process plants. PlantSight will provide increasingly comprehensive as-operated digital twin services, to incorporate Bentley’s AssetWise APM with Siemens’ operational technologies, MindSphere, and Teamcenter, for industrial plants’ asset performance modeling. And to accelerate owners going digital, Atos and Bentley announced a new strategic partnership to create and curate performance digital twins.

Keith Bentley, Bentley Systems founder and CTO, said “Our work with early adopters of iModelHub over the past year has confirmed to me that its unique strengths for alignment, accountability, and accessibility find their highest and best use, in conjunction with our reality modeling technologies, for enabling project digital twins and performance digital twins. I look forward to actively working with users and external developers to create an open ecosystem of innovation for iTwin™Services, leveraging the iModel.js library. I expect Bentley Systems to lead the infrastructure engineering community, as the ‘infrastructure digital twin’ company!” Learn More.

About Bentley Systems

Bentley Systems is the leading global provider of software solutions to engineers, architects, geospatial professionals, constructors, and owner-operators for the design, construction, and operations of infrastructure. Bentley’s MicroStation-based engineering and BIM applications, and its digital twin cloud services, advance the project delivery (ProjectWise) and the asset performance (AssetWise) of transportation and other public works, utilities, industrial and resources plants, and commercial and institutional facilities.

Bentley Systems employs more than 3,500 colleagues, generates annual revenues of $700 million in 170 countries, and has invested more than $1 billion in research, development, and acquisitions since 2012. From inception in 1984, the company has remained majority-owned by its five founding Bentley brothers. Bentley shares transact by invitation on the NASDAQ Private Market; strategic partner Siemens AG has accumulated a non-voting minority stake.

# # #

Bentley, the Bentley logo, AssetWise, Connected Data Environment, ContextCapture, iModel, iModelHub, iTwin, MicroStation, Navigator Web, OpenCities Planner, ProjectWise, and SYNCHRO are either registered or unregistered trademarks or service marks of Bentley Systems, Incorporated or one of its direct or indirect wholly owned subsidiaries. PlantSight is a trademark of Siemens AG and Siemens PLMS Inc. All other brands and product names are trademarks of their respective owners.

Carlson Connect now available for AutoCAD 2019

15.10.2018 23:18 Carlson Software MAYSVILLE, Kentucky, U.S.A. (October 2018) — Carlson Connect 2019 is now available on the Autodesk App Store, apps.autodesk.com, for $7.99. A collection of routines for transferring and converting data between Autodesk® Civil 3D®, and Carlson SurvCE and Carlson Survey, Carlson Connect 2019 runs within Civil 3D 2019 and uses the current Civil 3D data model. […]Carlson Introduces Hybrid+ as a Module for SurvCE/SurvPC 6.0

15.10.2018 22:37 Carlson Software MAYSVILLE, Kentucky, U.S.A. (October 2018) — Carlson Software introduces Hybrid+, a new paid module for SurvCE/SurvPC 6.0 that allows users to survey using both GPS and Total Station at the same time with all SurvCE compatible drivers. The Hybrid+ module incorporates a series of specially designed features to take advantage of the new multi-sensor setup […]Hybrid+ Surveying Case Study: Bringing Geodetic Coordinates Inside for Rodded Boretrak® Testing

15.10.2018 20:19 Carlson Software Available new in SurvCE and SurvPC 6.0 is powerful Hybrid+ Surveying, which is a mixed use of GNSS and robotic total station measurements. One of the many attractive features of Hybrid+ Surveying is GNSS Resection by Total Station. In July 2018, we used this feature to bring true geodetic coordinates, with true north azimuth, into […]Lead’Air Inc to introduce innovative TRACK’AIR ™ 2019 products and services at the Frankfurt 2018 Intergeo

15.10.2018 17:11 GISCafe.com Webcasts-Webinars 1)The MIDAS 2019 (Multi-Sensor Integrated Digital Airborne System). MIDAS can be configured to generate 5 cm (2 inches) GSD from 1,000 to 10,000 feet …Harris Corporation Reports Strong Fiscal 2019 First Quarter Results With Accelerated Revenue Growth Across All Segments

15.10.2018 16:53 GISCafe.com Webcasts-Webinars Revenue up 9% to $1.5 billion with a book-to-bill of 1.3EPS from continuing operations up 31% to $1.78

Operating cash flow up 23% to $117 million; …

Atos and Bentley Systems Announce Strategic Partnership to Create Digital Twins for Owner-operators of Industrial and Infrastructure Assets

15.10.2018 16:51 GISCafe.com Webcasts-Webinars LONDON — (BUSINESS WIRE) — October 15, 2018 — The Year in Infrastructure 2018 Conference – Atos, a global leader in digital …Bentley Acquires Agency9 to Realize Digital Twins for Every City

15.10.2018 16:50 GISCafe.com Webcasts-Webinars OpenCities Planner takes advantage of city-scale reality modeling to span GIS and BIMLONDON — (BUSINESS WIRE) — October 15, 2018 …

Siemens and Bentley Systems Announce PlantSight™ Digital Twin Cloud Services

15.10.2018 16:49 GISCafe.com Webcasts-Webinars Solution enables up-to-date, as-operated digital twins − synchronizing the real plant and its engineering representations − for more …Alteryx Announces Date of Third Quarter 2018 Financial Results Release

15.10.2018 16:48 GISCafe.com Webcasts-Webinars IRVINE, Calif. — (BUSINESS WIRE) — October 15, 2018 — Alteryx, Inc. (NYSE: AYX), revolutionizing business through data science and …Textron Aviation and NetJets Strengthen Industry-Leading Relationship with Option to Expand Fleet with Citation Longitude and Citation Hemisphere Jets

15.10.2018 16:47 GISCafe.com Webcasts-Webinars ORLANDO, Fla. — (BUSINESS WIRE) — October 15, 2018 — Textron Aviation Inc., a Textron Inc. (NYSE:TXT) company, and NetJets® …Topcon and Bentley Strengthen Constructioneering Initiatives and Programs

15.10.2018 16:47 GISCafe.com Webcasts-Webinars Constructioneering Academies expand insights, create changeLONDON — (BUSINESS WIRE) — October 15, 2018 — The Year in …

Kratos Partners with Harris Corporation to Bring Advanced Hand Held Radios to the Warfighter

15.10.2018 16:46 GISCafe.com Webcasts-Webinars Licensing Agreement Incorporates Kratos-Developed CDL Waveforms into Harris Tactical Radios for Enhanced ISR CapabilitiesSAN DIEGO, Oct. 15, 2018 …

Dell Expands UltraSharp Monitor Family with Innovations and Workforce Transformation in Mind

15.10.2018 16:45 GISCafe.com Webcasts-Webinars Dell UltraSharp monitors offer innovative design and technology, superb screen performance driving productivity for financial traders, bankers, …20181015 odborný referent v oddělení aktualizace a dokumentace KN

15.10.2018 16:05 ČÚZK - předpisy a opatření Katastrální úřad pro Středočeský kraj - Katastrální pracoviště Nymburk Vyhlášení výběrového řízení: odborný referent v oddělení aktualizace a dokumentace KN V části "Úřední deska", v sekci "Oznámení a jiná úřední sdělení" bylo vystaveno "Oznámení o vyhlášení výběrového řízení na obsazení systemizovaného místa odborný referent v oddělení aktualizace a dokumentace KN"20181015 odborný referent v oddělení aktualizace a dokumentace KN

15.10.2018 16:05 ČÚZK /Urady/Katastralni-urady/Katastralni-urady/Katastralni-urad-pro-Stredocesky-kraj/Katastralni-pracoviste/KP-Nymburk/O-uradu/Aktuality/20161013Rada-odborny-rada-–-informatik-(1)odborný referent v oddělení aktualizace a dokumentace KN

15.10.2018 16:04 ČÚZK - volná místa Katastrální úřad pro Středočeský kraj - Katastrální pracoviště Nymburk vypisuje výběrové řízení na místo odborný referent v oddělení aktualizace a dokumentace KNodborný referent v oddělení aktualizace a dokumentace KN

15.10.2018 16:04 ČÚZK /Urady/Katastralni-urady/Katastralni-urady/Katastralni-urad-pro-Stredocesky-kraj/Volna-mista/odborny-referent-v-oddeleni-aktualizace-a-dokumentodborný referent v oddělení aktualizace a dokumentace KN

15.10.2018 16:04 ČÚZK - předpisy a opatření Katastrální úřad pro Středočeský kraj - Katastrální pracoviště Nymburkvypisuje výběrové řízení na místo odborný referent v oddělení aktualizace a dokumentace KN

odborný referent v oddělení aktualizace a dokumentace KN

20181015-GaKO-10-2018

15.10.2018 15:27 ČÚZK - předpisy a opatření Český úřad zeměměřický a katastrální zveřejnil novou aktualitu: Aktuální číslo Geodetického a kartografického obzoru (10/2018) je k dispozici ke stažení.

Nové číslo GaKO

15.10.2018 14:30

ÚGKK SR

Nové číslo časopisu Geodetického a Kartografického Obzoru 10/2018

ERL Emergency 2019 – robots to the rescue!

15.10.2018 13:56 European GNSS Agency

In emergency situations, robotic systems play a key role in providing rescue teams with remote access to an emergency site. The ERL Emergency Local Tournament 2019 aims to foster advanced developments of autonomous capabilities and seamless navigation for emergency robotic systems.

The European Robotics League (ERL) is an innovative robot competition that stems from its predecessors - the euRathlon and RoCKIn competitions - and focuses on tasks that robots must execute in realistic emergency situations. The competition is composed of multiple local tournaments, held in different locations across Europe, in addition to a few major events.

The first of the challenges was announced in July 2018, and focused on land and sea robotic systems. The second, to be held in February 2019 at the premises of the Advanced Centre for Aerospace Technologies (CATEC) in Seville, Spain, will include air and land robots working in an outdoor/indoor environment. You can find more information about the challenges here.

Read this: Integrating GNSS in UAVs for faster SAR

Teams participate in a minimum of two tournaments (local and/or major) per year and get scores based on their performances. Each team’s top two tournament scores are then added together and the teams are ranked based on their cumulative score. Prizes for the top teams are awarded at the following year’s European Robotics Forum (ERF).

GSA Special Prize

The European Global Navigation Satellite Systems Agency (GSA) will award a special prize at ERL Emergency 2019 focusing on robots that make use of solutions based on Galileo and EGNOS.

For air robots, this challenge will involve two types of tasks: horizontal accuracy in landings at a specific geographic coordinate; and vertical accuracy while hovering at a specific geographic coordinate. For land robots, there will be only one type of task - horizontal accuracy during waypoint-based navigation.

Visual markers will be used to support the assessment of both types of task. To be eligible for the award, a team must have executed valid trials of the tasks. The team deemed to have achieved the best results will be declared the winner. For information on Galileo capable receivers and navigation kits for robotic systems visit https://www.usegalileo.eu/EN/.

Register now!

If you are interested, on 22nd October 2:00 PM - 4:30 PM CEST we will be holding a webinar on 'How to submit a winning proposal for the Emergency 2019 – robots to the rescue, competition!'

You can register to the webinar here.

Ready to join the ERL Emergency Local Tournament? Register your team here by the deadline of 29 October 2018.

Media note: This feature can be republished without charge provided the European GNSS Agency (GSA) is acknowledged as the source at the top or the bottom of the story. You must request permission before you use any of the photographs on the site. If you republish, we would be grateful if you could link back to the GSA website (http://www.gsa.europa.eu).

Program konference

15.10.2018 10:06 ARCDATANa stránkách Konference GIS Esri v ČR nyní naleznete časový harmonogram jednotlivých sekcí a můžete si přečíst abstrakty přihlášených příspěvků.

Vedle podrobného programu jsme připravili i časový rozvrh tematických miniseminářů, které se budou opět konat na stánku technické podpory. Z doprovodného programu se pak můžete těšit třeba na oblíbené postery, výstavu ke stému výročí založení československé vojenské zeměpisné služby a pětistému výročí Klaudyánovy mapy.

Byli jsme jedním ze sponzorů i řečníků v bloku Letectví odborné konference Doprava 2018+

15.10.2018 9:01 UpVision Byli jsme jedním ze sponzorů i řečníků v bloku Letectví odborné konference Doprava 2018+, která se včera konala v Praze pod záštitou ministra dopravy. Akce se s námi účastnil i CEO AirMapu David Hose a naše reklamní vlaštovka zaujala i Českou televizi. :-)Fotky zde:

https://plus.google.com/u/0/b/115833877689730865211/+UpvisionCz1/posts/87F1feubLHV

INSPIRE info day

15.10.2018 9:01 CENIA - národní geoportál INSPIRE INSPIRE info day pořádá CENIA, česká informační agentura životního prostředí v budově ČÚZK (Pod sídlištěm 1800/9, Praha 8, stanice metra C Kobylisy). Čas 10.00 - 15.00. Program bude zveřejněn v průběhu listopadu.Contex to Preview New Products at VIP Event in Las Vegas

15.10.2018 9:00 GISCafe.com Webcasts-Webinars Attendees to Experience the Latest in Wide Format Scanning and PrintingChantilly, VA — October 12, 2018 — Contex, the world …

Orbit GT signs strategic Smart Mapping deal with Singapore Land Authority at Embassy

15.10.2018 9:00 GISCafe.com Webcasts-Webinars Singapore, October 11th, 2018 -- Orbit GT and the Singapore Land Authority (SLA) signed a strategic and comprehensive deal at the Belgian …A More Informed View of City Business (ArcUser Online)

15.10.2018 9:00 GISCafe.com Webcasts-WebinarsKonference Otevřená data

15.10.2018 8:53 CENIA - národní geoportál INSPIRE Konference Otevřená data v Národní technické knihovně v Praze v čase 9.00 - 15.00. Program naleznete na stránkách konference. Registrace zde.INSPIRE info day

15.10.2018 8:53 CENIA - národní geoportál INSPIRE INSPIRE info day pořádá CENIA, česká informační agentura životního prostředí v zasedací místnosti Českého úřadu zeměměřického a katastrálního (Pod sídlištěm 1800/9, Praha 8). Čas 10.00 - 15.00. Program bude zveřejněn v průběhu listopadu.Ako GIS mení svet – 1000 GIS aplikácií

15.10.2018 8:30 GISportal.cz

GIS sú silným nástrojom, ktorý nájde domov takmer v každej disciplíne na svete. Milióny rozhodnutí sú podporované pomocou GIS. Pekný pohľad na GIS a jeho využitie v širokom spektre disciplín dáva nasledujúci sprievodca 1000 GIS aplikáciami (odkaz na stránku je dostupný tu). Je možné tu nájsť napr. rôzne prípadové štúdie, taktiež inšpiráciu pre rôzne študentské/podnikateľské GIS projekty […]

The post Ako GIS mení svet – 1000 GIS aplikácií appeared first on GISportal.cz.

Podzimní termíny školení open source GIS od GISMentors (PR)

15.10.2018 7:55 GISportal.cz

GISMentors vypsali na tento podzim celkem 6 kurzů open source GIS. Kurzy pokrývají spektrum desktop GIS (QGIS pro začátečníky a pokročilé, GRASS GIS pro začátečníky), databáze (PostGIS a PostgreSQL pro začátečníky) a zpracování prostorových dat v jazyce Python. Přihlaste se na kurz včas pro menší kurzovné , termíny se blíží. Pokud je vás skupina nebo máte zájem o více kurzů, neváhejte nás […]

The post Podzimní termíny školení open source GIS od GISMentors (PR) appeared first on GISportal.cz.

Nabídka témat bakalářských a diplomových prací [Katedra aplikované geoinformatiky a kartografie, byTopic]

15.10.2018 7:35 Katedra aplikované geoinformatiky a kartografie Přf UK Témata bakalářských a diplomových prací vypsaných pro školní rok 2018-2019 na katedře aplikované geoinformatiky a kartografie.Mapová aplikace

15.10.2018 7:30 Ústecký krajNově byla zpracována mapová aplikace"Rozhledny a vyhlídky v ÚK" Mapová aplikace Vás provede něk olika zajímavými místy, odkud jsou krásné výhledy do krajiny. Ať navštívíte nějakou vyhlídku či jednu z mnoho rozhleden v kraji, pohledy z nich Vás nikdy nezklamou a pokud se budet chtít s ostaními o výhled podělit, můžete nám zaslat pořízené foto a my ho můžeme zveřejnit.

Mapovou aplikaci naleznete na úvodní straně a také v sekci MAPY - > Turistika a cestovní ruch- > Rozhledny a vyhlídky v Ústeckém kraji.

Immersive Digital Twins Help Hubei Engineers Virtualize the Design of a 220-kilovolt Transmission Line

15.10.2018 2:00 Bentley SystemsThe Cha’anling-Ziaojiazhou region in China’s Zianning District is a highly developed region and home to 350,000 consumers of electricity. Historically, the region has experienced unreliable power supply, making consumer delivery unstable. Cha’anling-Ziaojiazhou is highly urban, with complex topology complicating the task of adding new power lines. Moreover, major highways that cross the region complicate the ability to add new transmission lines without impacting commercial and residential traffic. Further complicating potential improvements, the region borders the flood diversion area of the Yangtze River, meaning that potential flooding around future towers must be accounted for from the beginning. These factors mean that finding a solution to deliver improved power requires a new approach.

The Hubei Provincial Electric Power Survey and Design Institute was tasked with designing and delivering a new 220-kilovolt transmission line to provide power for a newly constructed substation in Xiaojiazhou. This transmission line is a significant step for improving the lives of the 350,000 daily users in Jiayu County. However, the obstacles that faced the Design Institute are significant. To solve these challenges, the engineering teams began by creating a fully immersive digital twin of the affected regions using ContextCapture. Modeling the entire region, including multiple cities and highways, established an immersive digital baseline from which the design studies could be made. Leveraging Bentley’s OpenBuildings Designer, Bentley Substation, and STAAD.Pro, Hubei’s engineers created a digital engineering model of the transmission line, which could be added to and combined with the immersive digital twin to visualize the new line and identify potential obstacles and issues. Analyses of the design could be performed and optimized to ensure that the new towers were structurally sound, to minimize interference with the urban and traffic areas, and to reduce design time compared to previous methods. The resulting design, leveraging Bentley’s iModel technology, was fully deployable into a three-dimensional earth view, ensuring that multiple stakeholders could review the planned route and design.

Implementing a completely digital workflow combined with immersive models has paid significant dividends during the design phase. In addition to increasing online collaboration, planned design time was reduced by 12 percent, checking time by 16 percent, and planned field work by five days. The design saved six houses in the region from being demolished, while ensuring that each of the major crossing areas were optimally designed. Design optimizations resulted in savings of material costs, with the new tower designs reducing weights by 1.2 percent and the total route length decreasing by half of a kilometer.

Through increased collaboration with contractors and design departments, design reviews to reduce conflicts between towers, lines, and the environment were optimized, reducing future rework and in-field problems. Using a digital design and collaboration model, the Hubei Provincial Electric Power Survey and Design Institute realized savings of more than CNY 6 million on a CNY 32.21 million project. The Hubei Provincial Electric Power Survey and Design Institute’s transformation to a digital environment has resulted in a design that not only saves money but also improves the lives of the residents in the Xianning District while preserving the environment.

Liang Zhang, an engineer with POWERCHINA Hubei Electric Engineering Corporation Limited, said, “The innovative use of Bentley software for the design of overhead electric transmission lines reduced design time by approximately 40 hours through multidiscipline collaboration. The full electric transmission line pole tower layout model, supported by the reality model, reduced the checking and auditing time by 32 hours. About 12 percent of the total design time and 16 percent of the checking time were reduced.”CCCC Creates a Digital Twin to Build a New Digital City in China

15.10.2018 2:00 Bentley SystemsAs part of a coordinated development plan, Zhongguancun will integrate the resources of Beijing, Tianjin, and Zhongguancun to build a new science and technology city. The CNY 2.2 billion project includes the design and construction of roads, utility pipelines, a 174,000-square-meter park, and green roadsides spanning 477,000 square meters. Given the large geographic span, wide construction area, and tight construction timeline, the overall project consultant CCCC Water Transportation Planning Design Institute (CCCC) implemented a collaborative BIM process to coordinate the many engineering disciplines to deliver the new digital city.

In keeping with the idea of a truly digital city that incorporates a municipality’s needed services, the project scope encompasses a wide range of utility, transportation, and environmental disciplines. Included within the project scope is the construction of 16 roads with a length of approximately 30 kilometers; a layout of rain and sewage diversion pipelines with a length of approximately 78 kilometers; water supply pipelines with a length of approximately 40 kilometers; intermediate water pipelines with a length of approximately 26 kilometers; gas pipelines with a length of approximately 43 kilometers; thermal power pipelines with a length of approximately 40 kilometers; power pipelines with a length of approximately 45 kilometers; and telecommunication pipelines with a length of approximately 39 kilometers. Additionally, the project team is responsible for designing and constructing a city park with an area of approximately 174,000 square meters. The roadside will be green with an area of approximately 477,000 square meters, and the river and water environment will be comprehensively improved. CCCC acts as the overall consultant and implementer of the BIM process on this project. The organization is responsible for the creation and application of BIM technology in the design, construction, and operation and maintenance of models in all stages. CCCC is responsible for setting up a BIM project management platform, building project digital assets, and assisting the construction of the regional smart park and smart city.

Using Bentley’s integrated BIM applications, including ContextCapture, LumenRT, MicroStation, Navigator, OpenBridge Modeler, OpenRoads, ProjectWise, ProStructures the team generated a comprehensive 3D model of the entire city. CCCC identified and remedied more than 200 collision points, optimizing design and reducing costly rework. Performing construction simulation facilitated construction management, shortening the construction period by 64 days to save CNY 6.6 million in costs. ProjectWise provided a connected data environment to streamline workflows and improve design efficiency. Integrating ContextCapture to generate a reality mesh from UAV terrain data collected on site enabled the team to facilitate earthworks planning, saving approximately CNY 40 million.

BIM Methodologies Help Beijing Water Increase Water Distribution in Northern China

15.10.2018 2:00 Bentley SystemsThe South-to-North Water Diversion Project is a major foundational strategic project to alleviate the severe shortage of water resources in northern China, especially in the capital of Beijing, to optimize the allocation of water resources, and to support the development of Beijing and Tianjin. The Beijing Institute of Water was tasked with this CNY 3.4 billion project to support the Hexi Branch sub-project in creating construction drawings of multiple pumping stations, water transmission lines, and water treatment plants.